Report from the international farrier competition

Report from the international farrier competition

The Werkman Spring Games is an event that brings together farriers from all over the world. For three days, farriers from different countries compete in the manufacture of complex orthopedic horseshoes, listen to lectures on scientific research in the field of biomechanics and veterinary orthopedics, current trends in the farrier industry, have the opportunity to discuss their concerns with colleagues, share their experience and knowledge, and also relax and relax during an evening dinner with like-minded people.

The Werkman horseshoe factory was founded in 1909 by the brothers Hero and Berend Werkman in Groningen, the Netherlands. Today the company is headed by the successors of the dynasty, fourth generation manufacturers: Christel Werkman and her brother Reian Werkman. It is noteworthy that the production is still located in Groningin, and not exported to Asia, as other firms do. The company pays great attention to the quality of products – horseshoes are constantly being refined, improved, the range of products is adapted to modern market requirements.

The Werkman team isn’t just running an expensive advertising campaign. The Spring Games are an event aimed at uniting the farrier community, motivating farriers for continuous self-improvement, educational activities and improving the quality of horse shoeing.

The Spring Games are held every two years (the competitions I am talking about are the fifth). Today it is one of the largest competitions in Europe, a world-class event in the farrier industry (in 2017 it was visited by representatives of 24 countries, more than 600 people were present, and 160 registered as participants in the competition). That is why it was especially exciting for me to debut, realizing that here I am the first and only representative from Russia.

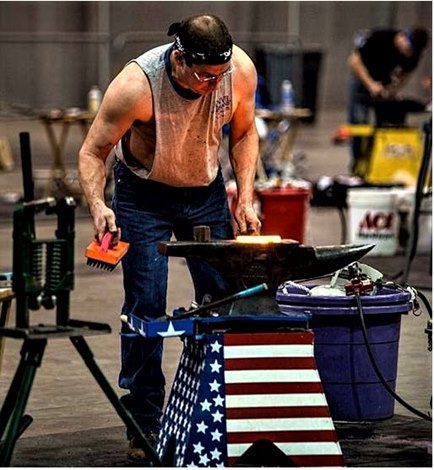

The competition among farriers was held in an indoor arena, where 40 workplaces were equipped. The organizers provided the participants with an anvil, a gas forge, a bucket of water and metal for making horseshoes, respectively, the participant had to have tools for making horseshoes, a vise, and, if desired, tables for tools for their own convenience.

The competitions themselves were held in three groups: beginners, intermediate and open (thus, each group made horseshoes of its own level of difficulty). Each participant went through four stages in two days, which were called “class” in the program and referee protocol. According to the sum of the points scored for all four classes, the six most productive participants from the beginners and the intermediate group were invited to the awards.

In the open group, where the models of horseshoes are of the highest level of complexity and the greatest competition in terms of the number of participants, only the best 20 on the basis of the results of the three previous classes are allowed to the fourth class “forged horseshoes with their own hand-forged horseshoes”. Getting into the top twenty already means getting into the awards. Three out of this twenty become absolute champions in the sum of four classes and receive bronze, silver and gold cups and valuable prizes.

In the group of beginners, all models of horseshoes are known in advance, that is, it was possible to train in their manufacture at home. In the intermediate and open groups, participants are notified in advance about three models of horseshoes out of five. Participants can see two horseshoes on the day of registration, so they have only one evening to think about and make a plan for making surprise horseshoes.

On the first day, participants and spectators began to arrive for dinner. We met many of our old friends. According to the Dutch, the weather was not typical for this time of year. However, neither the cold gusty wind nor the rain bothered anyone – everyone was in a great mood and friendly.

We went through registration and received a program, which detailed all the planned activities. From it I learned about the time and place of my starts.

In the evening there was a presentation of know-how from Werkman – a program for determining the balance of a horse. Then they showed the surprise horseshoes, and after that there was a gala dinner.

The second day, which is also the first day of the competition, started quite early for some, the first round started already at 8 am. I had to start in the fourth round at 11:45. I consider myself lucky to have the opportunity to look at the actions of other participants.

In the group of beginners in the first grade, we made: one rear-shaped horseshoe for the left leg with an extended

Here comes the moment X, 15 minutes before the start. I bring the tool, put everything in its place. I mark the blanks, time drags on insanely slowly, because of this, internal excitement, like a sea wave, rolls stronger and stronger every minute, and now I can hardly control my emotions, my head is foggy, my hands are wadded. I saw that my colleagues lit the horn and put in the blanks, I do the same on the machine. Time is frozen, I can only clearly hear the blood pounding in my temples, but I understand perfectly well that they are about to give a signal about the beginning of the round and then time will fly like a swift arrow, and it will be difficult for me to keep up with it.

That’s a whistle, but what an unfortunate accident! The gas forge burned very hot, and I put the blanks too early and too close to each other, so they welded together. What to do? I am shocked!!!! In my stove with borax, they sometimes don’t weld the first time, or even don’t weld at all, but then take it and cook it at the most crucial moment.

Somehow he cut the blanks and began to knock. Of course, this did not pass without a trace, and the appearance of my horseshoes was spoiled. In addition, on the front horseshoe, the clip ran off to the side, and this warped the entire horseshoe. But, as it turned out later, this model turned out to be the most difficult in our group, and, despite my gross mistakes, it still turned out not the worst.

The second class took place on the same day, in the evening. The time allotted for it was the same 60 minutes. Now I was a lot less worried. We had to make one model of the front form for the left leg with a narrower

On the third day, I also had to start twice: in the third grade, I would demonstrate fast forging, and in the fourth, I would pass the “eagle eye” test.

The essence of the third class is as follows: one horseshoe must be made in 15 minutes. In my case, the problem was that the strip from which this horseshoe is made is not in our country. The strip has a nail track rolled on a machine and a bevel along one edge, which performs the function of counter-coiling along the entire inner radius of the horseshoe. A fully rolled nail track gives, on the one hand, a stiffener, which is important, since the cross section of the strip is small. On the other hand, the nail track acts as a grouser.

After seeing how easily and naturally the young Italian Lorenzo Ginepri puts light, but very accurate blows, skillfully, as if effortlessly, juggling either a horseshoe, or pincers, or a handbrake, I decided to stick to his style of work. I note that in the end it was Lorenzo who became the winner in the competition.

In general, the work did not seem too difficult for me, and I had more than enough time. The task was to make the front shape, make the heels, punch holes and pull off one front clip with Bobpunch. The main thing was not to inflict strong blows that could leave faces and deform the canvas, giving shape, constantly straightening the horseshoe so that it would not twist and lead.

Before the collapse of the Soviet Union, we had a machine for rolling such strips at the Moscow hippodrome, which made it possible to significantly facilitate the work of blacksmiths and increase the rate of dressing horseshoes in the summer, when screw spikes were not required. Unfortunately, now we have to start all over again.

The fourth competition in my group was the Eagle Eye. Its essence is as follows: in a separate corner behind the screen, each of the participants is given 10 seconds to look at the hoof, while touching and measuring or sketching is prohibited. After that, you need to choose a factory horseshoe of the corresponding number, remove the clip and wait 40 minutes for the announcement of the start of the starts. During this time, the main task is not to forget the shape of the hoof.

When the start horn blew, the first thing I had to do was pull off the new clip. Then I tried to recreate an exact copy of the shape of the hoof from memory. Everything took 20 minutes.

It seemed to me interesting to analyze the command structure of the participating countries and in which subgroups they performed.

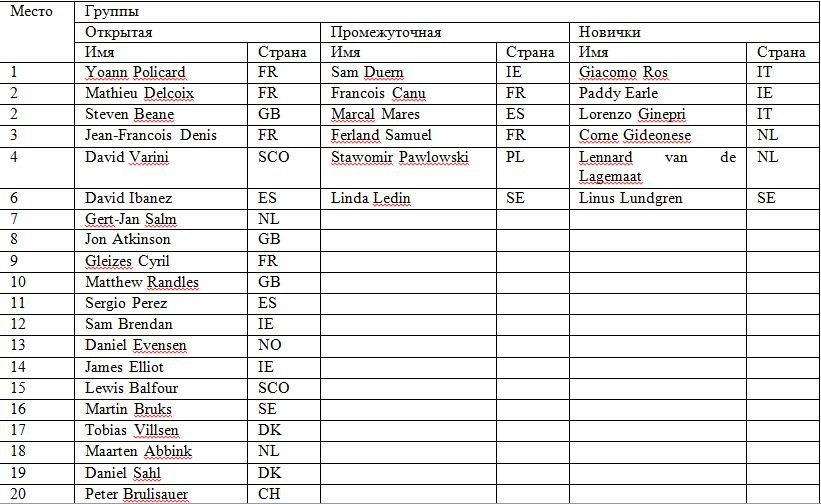

Table 1. Participating countries

In total, 137 people from 18 countries took part in the competition. There were 34 farriers in the novice group, 22 in the middle group, and 81 in the open group. The most numerous teams (16 people each) were in France and Ireland. The Netherlands and Sweden were represented by teams of 13 people. 10 people came from the Czech Republic, 9 from Great Britain and Spain, 8 from Denmark, Austria and Germany. The rest of the countries came in small groups. Russia was presented for the first time.

Having studied the protocols of the competition in detail, and also taking into account my information about the Games held earlier, I will allow myself to draw some conclusions.

In Europe, today we can talk about such farrier schools as the British one, whose roots go back to the distant 1356. Farriery has been brought to a high level in France, Holland, Ireland and the Scandinavian countries. Germany and Austria also have their own schools, but some stagnation should be noted in them, but Spain, on the contrary, has shown significant progress in the blacksmith business in recent years. This year, two young participants performed brilliantly for Italy, which once again proves that in this country there is someone to train new wonderful specialists. The Czech Republic and Poland performed at these competitions with dignity, but the Finns looked very pale. I have not seen the work of the representatives of Switzerland, and I also did not find anyone in the starting protocols.

The absolute winners were the French: Yoann Policard and Mathieu Delcoix, and the champion of three Games in a row, Steven Beane, this time was awarded only bronze. Although in the fourth class of the actual shoeing of a horse “for his own hand-forged horseshoes”, he was not even close to equal, his lead with 2nd place was 2,4 points, despite the fact that the difference between second, third and fourth places was an insignificant 0,1 points, and Yoann Policard was only in fifth place in this class.

Table 2. Protocol of competition winners

I consider my own debut at the Werkman Spring Games to be successful – in the final ranking I settled in 19th place, while in the third and fourth grades I managed to take 7th place. This suggests that even on your own, without a mentor and coach, you can prepare for this kind of competition – if only there was a desire!

The 2017 Spring Games are over and we are home again, but the atmosphere of solidarity and corporate brotherhood that has reigned all these days will remain in our memory for a long time to come. I am firmly convinced that I will definitely come to the next Games, it is a pity that they will take place only in two years, but there is time to train and, perhaps, to assemble a full-fledged Russian team of farriers!

Anatoly Zhukov; http://your-farrier.com/