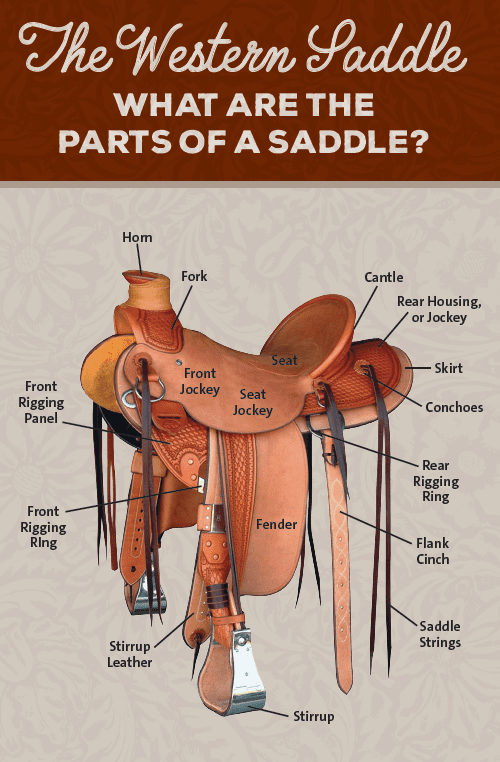

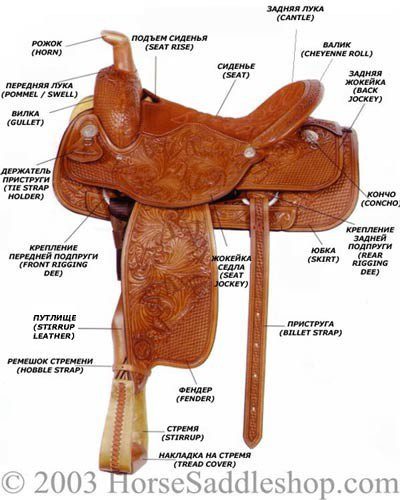

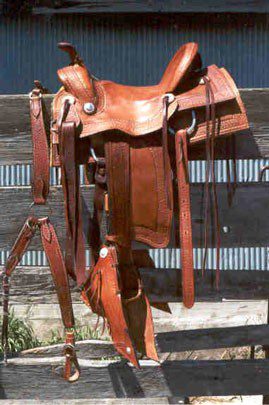

Western saddle and its components

In this article, we will show what a cowboy saddle looks like and what it consists of. Each part and detail of a Western saddle has not only a purely aesthetic, but also a strictly functional purpose. The three most important components are the tree, the seat, and the girth attachment. If these three components are done correctly, there is a chance to get a good, quality saddle. If even one of them is wrong, the saddle will never be right.

One of the most important parts of a saddle, its base, although invisible in the finished saddle, is the saddle tree. Without a quality tree you will never get a quality western saddle.

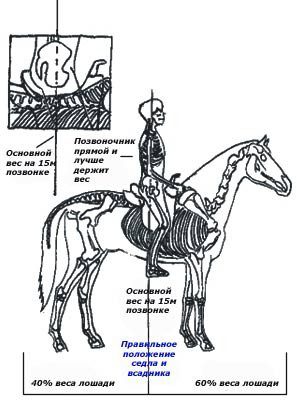

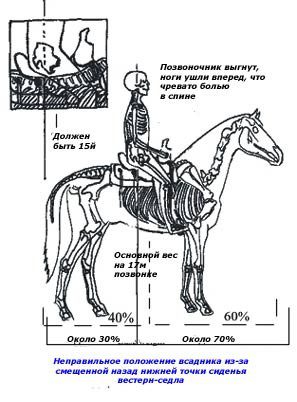

The task of the tree is to evenly distribute the rider’s weight over the horse’s back. The weight of the rider is distributed through the shelves, so the more evenly they fit on the horse’s back, the more comfortable the saddle will be for him. The distance between the shelves should be sufficient so that the saddle does not press on the spine, and the height and width of the fork should be sufficient so that there is no pressure on the withers and shoulders of the horse.

Contents

wooden tree

Western saddle trees were traditionally made of wood (hence the English name tree, which means both “tree” and “tree tree”). In the production of trees, relatively soft wood species are used, capable of a certain flexibility: yellow pine, beech, ash, poplar, etc.

A wooden tree is additionally strengthened by covering it with rawhide, buffalo skin, or fiberglass.

- Rawhide: After the wooden tree is ready, it is covered with a piece of wet rawhide, which, when dried, fits the tree, making it very strong and slightly elastic, which allows it to absorb shock and withstand a huge load, and also protects the tree from sweat and weather troubles.

- Buffalo skin (Bullhide): usually denser and thicker than rawhide. It is believed that the tree covered with buffalo skin is more durable and at the same time, due to the thickness of the skin, it is better to hug the horse’s back. Such lenchiki are considered the best.

- Fiberglass: a relatively recent innovation in saddlery. Fiberglass has proven to be a very durable material, well able to protect the wood parts of the tree. This is a more economical option than rawhide or buffalo leather.

Lenchik Flex

When the flex trees first appeared, they caused a lot of skepticism. However, today it is already clear that horses really like such trees. Saddles with such trees are relatively lightweight compared to wooden trees and provide closer contact between the rider and the horse.

However, it is a mistake to assume that if the tree is called “flexible”, it can fit any back – firstly, only the shelves are flexible in flex trees, while the front and back pommel remain rigid. Secondly, the flexibility of the flanges implies an amplitude of several millimeters, which is enough for a more comfortable fit on the horse’s back with a suitable saddle, but not at all for a saddle that is too narrow or too wide for the horse.

Saddles with flex trees are not recommended for use on the ranch, however, they are fine for walking and arena work.

You can see saddles with flex trees on the website www.horsesaddleshop.com

Synthetic tree (Ralide)

The best of the synthetic materials for the manufacture of trees is ralide. The term Ralide denotes both a material (a type of synthetic polyethylene) and the name of an American company that patented the production of this material. Trees are cast by molding, which reduces the cost of their production and makes them very economical. At the same time, ralid trees are quite durable, but they have certain features. Firstly, they are not as plastic as wooden trees. Secondly, since they are molded, this implies a limited number of sizing options. Thirdly, plastic holds the nails and screws used in tree assembly worse, which reduces their durability.

Of course, synthetic trees have their niche in the market – they are a budget alternative for infrequent walks. However, if you need a quality saddle for any demanding job that will last you a lifetime, opt for a buffalo leather tree.

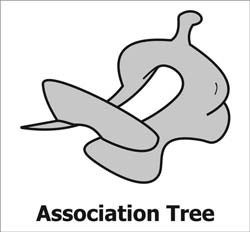

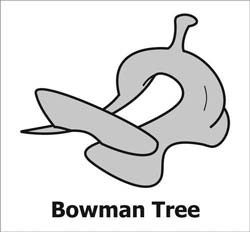

Tree forms

As already mentioned, there are no unified standards in the production of saddles, so each manufacturer has his own idea of uXNUMXbuXNUMXbthe size of the saddle, and they can call the same tree shape differently. However, most often the name of the tree is determined by the shape of the front pommel. The remaining parts are shelves, back pommel, horn, etc. may be different, but if the shape of the front bow is the same, then the tree will be called the same. So if you see the name Wade, Association, Bowman, etc., you should know that this name refers mainly to the shape of the pommel.

There are also forms of tree shelves: for example, Arab shelves are shorter than standard ones. The shelves called “Cutting” (used mainly in cutting saddles, and also very often in reining saddles) are thinner and narrower, for closer contact between the rider and the horse. On the other hand, the Arizona style ribs are thicker and wider, distributing the rider’s weight over a larger area of the horse’s back. Arizona bolsters are more suitable for long-term riding and are used in ranch, all-round, etc. saddles.

The front bow connects the shelves of the tree and does not allow them to diverge to the sides. It defines the shape of the front of the saddle and comes in two main types: smooth (slick or A-fork) and convex (swell). The convex front bow can be full or carved (undercut).

Different types of pommel emerged as a result of different uses of saddles, as well as the preferences of riders. Early saddles most often had a flattened pommel. The bulbous pommel was considered more reliable when riding wild mustangs in rodeos. Later, this form became widespread on saddles for riding rough terrain and for competitions.

At the same time, in California and the Western United States, where the traditions of the California Western style (vaquero style) are preserved, saddles with a flattened pommel are most common.

The width of a flattened pommel usually does not exceed 20 cm – 25 cm, while a convex pommel has a width of 28 cm to 35 cm.

FORK (GULLET)

A fork is a recess under the front pommel, located above the withers of the horse. The length and width of the fork determines how comfortable the saddle is for the horse. The fork of the saddle must provide sufficient space between the withers of the horse and the pommel so that the pommel does not press on the withers of the horse.

As a general rule, three or four fingers should pass between the withers and the front pommel (without a pad and without a rider on top).

The fork should also not be too narrow or too wide. A fork that is too wide will cause the saddle to again lie on the withers of the pommel. A fork that is too narrow will prevent the saddle legs from resting fully on the horse’s back, causing the rider’s weight to push the horse’s back too close to the spine.

The comfort of the rider and, perhaps, the horse depends entirely on what kind of seat the western saddle has, how it suits the rider and the tasks he performs.

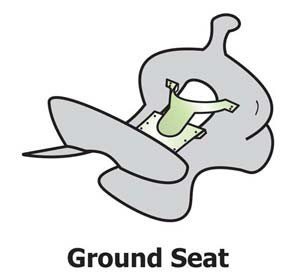

The seat starts by creating the seat base (ground seat). This is no less important part of the work than the production of a tree.

The base itself can be made in different ways: from a metal plate, from very thick leather, or, if the tree is molded from plastic, molded together with the tree.

Pieces of leather, which are cut from the densest parts of the skin, are superimposed on the finished tree, covered with rawhide.

This is followed by several stages of gluing, which take more than one day. Then another piece of leather is applied, which plays the role of a rigid lining in the front of the seat. All gluing steps are repeated. The saddle is allowed to dry for a few more days. From above, all this is closed with another piece of skin. The whole process of gluing, soaking and shaping is repeated again.

In this way, a seat base is obtained, ready to take on the weight of the rider. The last to cut are slots for putlisch and a hole in front of the front pommel (if necessary). Everything is glued again, and the seat base is ready!

It is very important that the deepest point of the seat (pocket) is in the middle between the pommel and the holes for the putliches. This will provide the rider with a truly centered seating position, unlike many modern saddles that put the rider in a “chair” position. This seat allows the rider’s feet to be directly under their center of gravity, and allows the rider to ride on longer stirrups and take a deeper seat, taking pressure off the knees and ankles. The rider ceases to constantly struggle for the correct position in the saddle.

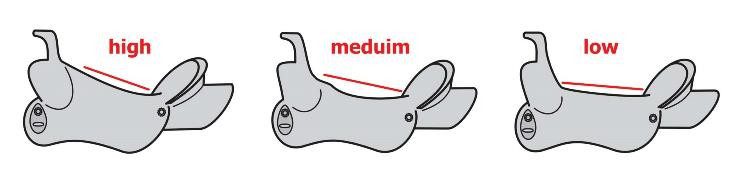

The base of the seat can also have a different angle of inclination to the front pommel. The flat seat allows more freedom of movement for the seat and hips of the rider, while the higher angle of the seat provides a more stable position in the saddle.

The choice is determined partly by the preference of the rider, partly by the purpose of the saddle. For example, barrel racing saddles often have high angle seats, while cutting and roping saddles tend to have flat seats.

Often the seats are made with soft padding for the comfort of the rider. However, it should be remembered that the inconvenience of the seat most often lies not in its rigidity, but in an unsuccessful design. In this case, an additional soft lining is unlikely to help. The correct seat base is not flat, but slightly convex and tapers forward, otherwise the rider will feel like he is trying to sit astride a table.

Also, in order for the seat to be comfortable, it is important to choose it in size.

The way in which the girths are attached to the saddle is one of the most important aspects of the safety of the rider in the saddle, as well as the comfort of the saddle for the horse.

First of all, it must be remembered that the bindings must be located absolutely symmetrically on both sides of the saddle, clearly opposite each other. If the mounts are shifted relative to each other in one direction or another, it is better to immediately get out of your head the thought of buying such a saddle!

Findings

Fasteners can be in the form of rings, or half rings, or metal plates. You can find any combination for the front and back girth. In high-quality saddles, fasteners are made of stainless steel, brass or bronze – such fittings do not rust or crumble.

Mounting methods

There are two ways of attaching accessories to the saddle: traditionally, to the tree and a newer way – to the skirt. The traditional way of fastening to a tree has always been considered more reliable, but with this fastening, the entire thickness of a few turns of the plow (especially if it is tied with a “tie”) plus the skirt falls right under the rider’s knee. The “skirt” binding has proven itself to be no less durable and, moreover, causes less inconvenience to the rider’s leg, because. the pristruga turns out to be lowered, Also, it doesn’t fit over a skirt. In this case, the half ring is usually attached to a metal plate between the layers of the skin of the skirt.

While the skirt binding is rarely found in routing or cutting saddles, it is a fairly common option in barrel racing, reining and plunging saddles precisely because it provides better contact between the rider’s leg and the horse’s flank. With fastenings in the skirt, the girth can be tightened not as much as when attaching the rings directly to the tree. At the same time, one of the advantages of attaching rings to a tree is that they are relatively easy to repair or replace as the saddle wears out. The ring sewn into the skirt can only be changed together with the skirt.

mount in the form clamping

plates in the form of a semicircle

fastening to the lanyard.

fastening to the lanyard.

Note:if both half rings are attached to the tree, then there must be a connecting belt between them so that the rings do not spread.

fastening “in a skirt”

fastening “in a skirt”

Mount location

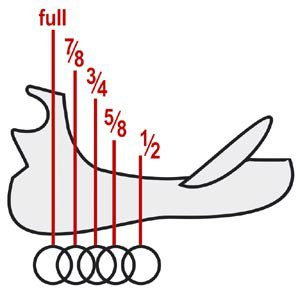

While the rear girth attachment is always located under the pommel, the front girth attachment can have various positions called full, 3/4, 7/8 and center-fire or 1/2.

A mount that places the girth exactly halfway between the pommel and pommel (under the center of the saddle) is called centered. In modern saddles, such a mount is quite rare, it can be found in army-style saddles, as well as in some trail saddles. This fastening requires a fairly wide girth – at least 6-8 inches (15-20 cm).

The 3/4 position places the girth midway between the pommel and the center of the saddle, i.e. at a distance of 3/4 of the distance from the rear pommel to the front pommel.

The 7/8 position is 1/8 closer to the pommel than the 3/4 position, while the full position places the girth exactly under the pommel.

Full and 7/8 bindings usually require a rear girth to balance the excessive pressure on the front of the saddle.

The choice of position for attaching the girths is mainly determined by the structure of the horse. The girth should fit at the narrowest point of the horse’s chest (it will move there anyway) and at the same time ensure that the tree legs are positioned two fingers from the shoulder blade so as not to interfere with the movement of the shoulder.

Usually the narrowest point is about a hand’s length from the horse’s elbows. Therefore, most horses are most suited to the 7/8 mount, and most saddles are made with this mount. However, depending on the constitution of a particular horse, a full or 3/4 binding may be more suitable for him.

Some manufacturers make universal mounts that allow you to mount the girth in any of three positions: full, 7/8 or 3/4.

universal mounting option

universal mounting option

ways to tighten the girth to get different positions

ways to tighten the girth to get different positions

The purpose of the girth is to pull the saddle and hold it firmly on the horse’s back. The most common type of front girth is a rope girth.

In the old days, such girths were made from horsehair: a better version – from a mane, a cheaper one – from a tail. However, such girths, being very strong and durable, did not absorb horse sweat well, which often led to scuffs. Cotton has the best ability to absorb moisture, but when wet, cotton quickly loses its strength. Therefore, the most suitable girths from this point of view are mohair (a mixture of angora and wool), which absorb moisture well and, when wet, become even stronger.

Recently, girths made of neoprene and other synthetic materials have become very popular, but I would like to note that what is not always pleasant to the touch of a human hand is also pleasant to horse skin.Remember that ventilation is the most important thing for a horse!

There are also leather girths, as well as those hemmed from the inside with faux fur or other soft material. Such girths can be used in the arena and in the show arena, but it is better to refrain from them on long trips.

Girth length

The length of the girth is measured in inches from the edge of one ring to the edge of the other ring. The most common sizes are: 30, 32, 34 inches (size is expressed in even numbers only).

Width braces

The girth width is measured in inches, and the width of rope girths is often measured in the number of threads. As a general rule, the closer the girth attachment is to the pommel, the thinner the girth should be. So, when fastening full, a girth is used in 17 threads, when fastening 7/8 – in 19 threads, and when fastening 3/4 – in 21 threads.

Using a girth that is wider than required may cause abrasions and wounds as the horse will constantly touch the girth with his elbows.

Important:when buying a rope girth, be sure to see that in the middle of the girth there is either a strap made of leather or dense braid sewn across, or the weaving of the threads is very tight, otherwise such a girth will roll into a tourniquet and cause great inconvenience to the horse!

Recently, the so-called “roper” girths have become very widespread – very wide, moreover, expanding in addition to the middle.

Many riders think that the wider the girth, the more humane it is for the horse. However, such girths create the effect of a corset, which is completely uncomfortable for the horse, especially with prolonged use, especially if such a girth has a leather insert in the middle. Therefore, while such girths are quite justified for rouping, where during the lassoing of the steers on the saddle, as well as on the horse’s abdominal muscles, they should not be used for normal riding.

If it happens that you only have a rope girth at your disposal, try to tighten it more loosely than a regular girth (unless you are going to be roping).

Buckles

Girth buckles are used to attach girths. Most often they are of three types: a ring (or half ring), a ring with a tongue and a ring with a crossbar and a tongue.

The simple ring is mostly found on the cheapest girths and also on rodeo girths. A pristruga to such a ring can only be attached with a knot. The tongue allows you to fasten the girth, removing the thickness of the knot from under the rider’s knee. However, simply attaching the tongue to the base of the ring often results in the ring stretching into an oval over time, and the tongue no longer holds the cut. Many riders continue to knot their harness despite the presence of a tongue that is left sticking down – this is a safety violation and can lead to an accident.

The strongest rings are rings with a cross bar, to which, in turn, a tongue is attached. This design does not allow the ring to stretch, in addition, the tongue is shorter and therefore more durable.

Often the buckles on the left side of the girth are also provided with a roller (or other tricky devices) to facilitate the process of tightening the girth.

Ideally, the girth rings should be made of stainless steel. Iron or chromed iron rings are prone to rust and are best avoided.

In the middle of any girth, small half-rings are sewn on both sides: one of them is intended for attaching the girth, as well as any auxiliary devices for working with a horse, the second is for attaching a strap connecting the back girth to the front.

The back girth appeared on the Western saddle when cowboys began not only to catch bulls on a lasso, but also tightly tie the other end of the lasso to the horn. The back girth kept the saddle from tilting forward when the lasso was pulled sharply. At the same time, the back girth was not tightened tightly, since at the moment of the jerk the horse strained the abdominal muscles. Similarly, the back girth helps the saddle stay in place when the horse stops abruptly.

Since most western saddles have rear girth attachments, many riders feel they should use them. However, if you’re not into roping, you probably won’t need a back girth at all.

There is a widespread myth that the rear girth keeps the saddle from sliding forward on steep descents, however, this is not the case.

The back girth is usually leather, with buckles at both ends. Loops for holding the free ends of the girth are often made very wide to prevent the rope from accidentally getting stuck between the end of the girth and the girth. A connecting strap must be attached to the middle of the back girth, which, when saddled, is fastened to the ring in the middle of the front girth.

If for some reason you decide to use a back girth, remember the following rules:

- The girth should not be too tight, but it should not be too loose either. If the back girth dangles, there is a chance that the horse will catch on it with a hoof or a branch will fall between the girth and the horse’s stomach, etc.

- between the front and back girths, there must be a connecting strap fastened, which keeps the back girth from slipping to the horse’s groin.

- saddle horse, always tighten the front girth first and then the back girth.

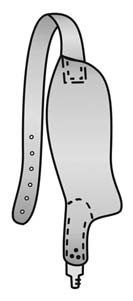

Front left pruning (Latigo)

Nylon gaiters are much thinner than leather gaiters and do not create as much thickness under the rider’s knee as leather gaiters, although they are not inferior to the latter in strength. However, nylon harnesses are more likely to chafe the horse’s skin if the skin is very sensitive. You also need to remember that nylon, unlike leather, does not stretch at all, and in order to tighten the nylon girth, much less effort is required. Therefore, be careful not to drag the horse.

The left hand girth is usually made 3,8 to 5 cm (1,5 to 2 inches) wide and about 1,8 meters long, as it passes between the saddle ring and girth ring several times when tightened.

If you need to replace the strut, do it like this:

1. Wrap the harness around the ring (buckle) on the saddle, with the short side facing you. Pass the leather cord (it is usually sold with a plow) into the two lower holes.

2. Then thread both ends of the lace back out through the top holes.

3. Pass the ends of the lace through the loop between the bottom holes.

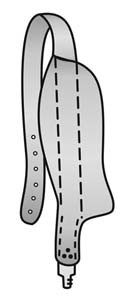

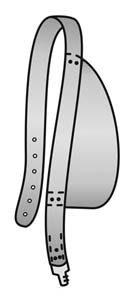

Front right prig (off billet)

The front right brace is usually fastened once and not touched again, so most often it looks different than the left one, which must be unfastened and re-tightened each time. Some manufacturers make identical pruning left and right.

There is a lot of pressure on the right strut, so it must be double.

The width of the right pruning is usually also from 3,8 to 5 cm (like the left one), and its length can be from 45 cm to 60 cm.half-breed off billetand attached as follows:

Check the right hand plow regularly and change it as soon as you notice that it is worn.

Rear prirugi (flank billets)

The rear girths do not carry the same load as the front girths, since the rear cinch is practically not tightened, therefore they are usually made single.

The length of the rear pruning is from 60 cm to 90 cm, the width is from 3,8 cm to 5 cm.

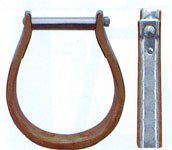

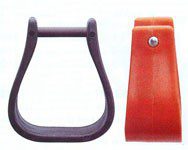

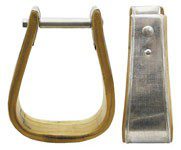

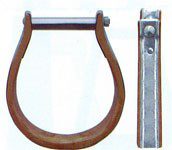

Western saddle stirrups were originally made from a single piece of wood, “steamed out” and bent into the desired shape. Now stirrups are made from metal (aluminum, stainless steel, etc.), and from plywood, and from synthetic materials. Stirrups can be all-metal, or they can be wooden with a metal “cover” on the outside, they can also be covered with leather – completely or partially (footboard).

In general, the stirrup of a cowboy saddle should be heavy – this way it “hangs” better (do not forget that putlischa-fenders are made of dense thick leather, so lightweight stirrups can “bump”) and it is easier to catch it with your foot. But lately, sports saddle manufacturers have been looking for ways to reduce the weight of the equipment – for rider and horse comfort in arena work and performances, for example, barrel racing saddles are generally the lightest. Therefore, manufacturers began to look for new lightweight durable materials. But in everyday life and work, heavy wooden stirrups remain the best option.

Stirrups come in different shapes and sizes, which is primarily due to their applied purpose. The stirrup that “lives” on a rope saddle looks much more massive and fundamental than a round, thin stirrup from a cutting saddle. The main parameters of the stirrups are the height measured along the inside (from the shelf to the roller) and the width (in the widest part). Another parameter – “depth” – the size of the “end” of the stirrup: it can vary from an inch (OxBow cutter) to 6 inches (some bell-type stirrups).

The stirrup depth is chosen based on your main line of work and riding style. If you drive “for yourself” – then choose simply based on your own convenience and habits. Deep stirrups are the best choice for long rides, thinner stirrups allow for clearer commands and more control in training and performances. But no matter which stirrup you choose, the main parameter is probably the width. It should be enough for your boots, because no one wants to “hammer their boots into the stirrup” and then ride in such cramped conditions.

Stirrups come in several types and differ in frontal and lateral appearance.

Front view:

roper Oxbow Overshoe

Side View:

visalia Moran Bell bottom

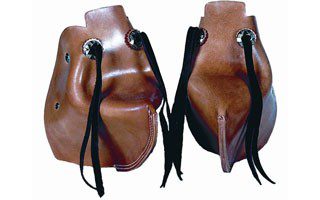

Tapaderos are sometimes attached to stirrups. Tapas – came from the cowboys of the southwest – leather “hoods” on the stirrups, which originally served to protect the boot from dust and branches, as well as from the cold (winter version), but now they have become more of a decorative element.

Now there are also many “modifications” of stirrups. Oversized – for voluminous winter shoes (for example, Smith often makes stirrups for the Russian winter on his saddles – you can ride in high boots in such stirrups), safe ones that unfasten when the rider falls, and so on. In addition, so that you do not have to turn the stirrup, you can buy a leg saver – stirrups attached to the “adapter”, such stirrups are always turned into the correct position at 90 degrees to the fender. And for a “relaxed” landing on a high horse, a design was invented that “lengthens” the stirrup for the duration of the landing.

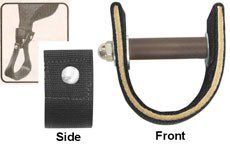

Leg saver Breakaway Step-up

STIRRUP HOBBLE STRAP

The stirrup strap is a narrow strip of leather fastened with a buckle. Its main purpose is to pull the loose ends of the putlish under the fender. The strap should be tightly fastened at the very bottom of the trouser, just above the stirrup..

Often these straps are lost, and some riders take them off on purpose, as it seems inconvenient for them to unfasten and fasten the strap all the time when adjusting the length of the stirrups. In fact, this is a very important detail for the safety of the rider. Without a strap, the stirrup can (and often does) turn up and out of the way when the rider falls and press his foot against the fender. Get a real trap.

The strap has another useful function: if the putlish suddenly breaks on the old saddle, the strap will help to keep the stirrup in place for some time.

Do not neglect safety precautions and do not remove the straps from the putties, and if they are lost or torn, buy new ones, and temporarily tighten the fender and putlish with any suitable piece of rope, lace, dog collar, etc.

TREAD COVER

To improve the grip of the boot with the stirrup, the stirrup shelf is wrapped with special overlays. Traditionally, they are made of leather, even if the stirrup is completely covered with leather (here the overlay also serves to protect the main skin from abrasion during operation). But lately there have also been linings with rubber inserts.

Some stirrups come without a lining at all.

Fastening stirrups to a Western saddle is quite noticeably different from the classic. This “fastener” consists of two independent parts connected to each other: the fender and the actual putlisch. Sometimes it seems that you can get by with just one leg, and the fender is not particularly important, but it serves to protect the rider’s legs.

PUTLYSHA — long leather strips. It is very important that they are made of high quality thick leather. If for some reason it is necessary to replace one of the putties, it is advisable to change them in pairs so that the skin of both putties is the same, otherwise the “stretching” may turn out to be different.

Ideally, the width of the saddle should be 3 inches, but in some cases, strips of leather are taken narrower (2-2,5 inches) in order to reduce the weight of the saddle. Some firms use thinner leather in order to reduce the cost of production. The first option is found on show-class saddles, but the second is found on cheap saddles of dubious production.

Fender– a long, wide piece of leather that lies between the horse and the rider’s leg and serves to protect against horse sweat. They must be made of thick leather of very high quality, as well as putlishas.

Fenders come in a variety of shapes and widths and often depend on the overall design of the saddle. Closer to the saddle, the fender narrows to the width of the trouser, so that an extra layer of skin does not interfere under the jockey, which can create some inconvenience for the rider.

Fenders are connected to putlishes in three ways:

Full Length (1) Half Length (2) Old Style (3)

(1) The putlishe is stitched along the entire length of the fender from the inside. This is the most common way in modern saddles.

(2) The putlische is attached to the top of the fender. It makes the fenders more comfortable for legs.

(3) Putlishche lies on the outside of the fender, attached at the top and bottom. Such a connection occurs on buckaroo saddles.

Ekaterina Lomeiko (Sara)

The material is posted with the permission of the copyright holder RideWest.ru

Gusika 10 February 2017 city

Gusika 10 February 2017 cityGreat article! There is a lack of such training material. Thank you! Answer

EquestrianI 17 February 2018 city

EquestrianI 17 February 2018 cityVery useful. Thank you. Answer